| Cable Management & Protection GuideCable management & protection can play a vital role in your 12 volt set-up. Preventing abrasion, protecting from exposure to high temperatures or chemicals, or simply keeping your cable tidy can be well worth undertaking. Cable protection not only means sleeving; there are a host of options to help create a safe & neat wiring loom. So which type is best for you? In this guide, we will walk you through the benefits of each type to help you get the best for your setup. Protecting against high temperatures Protecting cable from exposure to high-temperatures in areas such as engine bays is a good exercise. Although cable insulation itself provides some protection, sleeving such as convoluted sleeving or heat shrink sleeving can usually cope with much higher temperatures. This protection stops thermal damage to the cable insulation which could expose the inner core and result in potential fire risk or poor connection. Cable ties or clips can also stop cable moving, preventing it from coming into contact with parts of your vehicle where temperatures may be higher than the rated tolerances. Protecting against abrasion Cable insulation being rubbed against exposed surfaces can also lead to problems. If the copper core is exposed and touches bare metal, this can cause a short that will blow the fuse in that cable and potentially damage your connected equipment. If there is no fuse or too much of the cable is unprotected by the fuse, then you run the risk of an electrical fire. By protecting the cable with sleeving that has good abrasion resistance, you reduce the risk of the insulation of the cable being damaged and causing a short. Using cable ties, clips etc. can help hold the cable in place to prevent movement that would cause such abrasion whilst the vehicle is in motion. Tidying cable Having a lot of cables in your installation can be messy, confusing and tricky to manage. Using sleeving, clips or ties can all help keep your loom tidy & together which can make it easier when routing. Using sleeving like heat-shrink sleeving or PVC sleeving also allows you to apply labels to help you, in the future, determine which section you need when investigating issues or upgrading. Having your cables in one run can also make routing a lot easier as you only need to feed the cables through once. Cable grommets

Grommets are used when feeding the cable through bulkheads, panels or other such areas. These are usually made of soft PVC and prevent the cable from rubbing against the exposed metal, so protecting against abrasion. Cable ties & bases.

Cable ties can be very handy at keeping all your cable neat and tidy and preventing it moving around (which can lead to abrasion). If you are unable to find an area to tie a cable tie to then a cable tie base can be a purchase that can either be screwed into the vehicle or stuck to a flat surface using a self-adhesive pad attached to the back of the base. Cable ties are also easy to remove and re-attach should you ever need to revisit the loom to either add wires or change anything about the installation. Cable clips

Another great way of holding your cable in place; cable clips are simply screwed into place and form a clamp around the cable. Positioned at regular lengths along the cable run, they prevent unwanted movement. Some options will come with sticky pads if you're unable to screw into the mounting surface. Convoluted sleeving

Convoluted sleeving is a semi-rigid tube, often made of nylon, that a cable can be inserted into for protection. Available in a split and un-split variants, this is often used where multiple cables are running side-by-side and require protection. Due to its round profile, this sleeving is not the best for installing in tight spaces but it is very handy for areas that are subject to high heat & chemicals. There are several adapters also available such as junctions, connections and end caps to help you create a neat and protected cable run. For unsplit sleeving, the cable must be pulled through using a 'mouse' which can be tricky with long runs, but the completely solid nature of it means that it it fully protects the cable from the surrounding environment, so it's ideal if you're running the cable externally on a vehicle. The split variant is easier to use as it can be applied over the cable once it's been routed in place (and we have tools available to help with this), but the split does mean there's the chance of liquids getting to the cable.

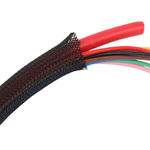

Expandable braided sleeving

This type of sleeving is made from polyester and is highly flexible, durable and is flame retardant & halogen-free. With an open weave design, it is not only easy to work into corners but you can also feed cable through the open weaves to branch off your harness to different areas, and it can stretch to accommodate a wide range of cable bundles sizes. The polyester is also UV-resistant which offers some protection to your cable against sunlight that can cause the insulation to become brittle over time.

Spiral wrap sleeving

Similar to convoluted sleeving, spiral sleeving offers great protection against abrasion. Easy to cut & wrap around your loom, this sleeving also allows you to branch out individual cables from the gaps between the spirals and it can accommodate a range of cable bundle sizes. This sleeving is one of the easiest to remove, meaning new cables can be added easily and repairs on existing cables carried out quickly.

PVC sleeving

One of the most basic types of sleeving, PVC offers a no-frills cable protection option but is still in very common use (e.g. cables leading from the handlebars of motorbikes) . PVC sleeving provides great chemical protection and can be used in lots of areas, but it does require cable to be 'moused' through and unslightly white creases can appear if the sleeving is folded (these can be removed by gently heating).

Heatshrink sleeving

Most people will be familiar with this type of sleeving which shrinks down in diameter when a relatively high heat is applied. It offers great flexibility whilst being suitable for use in areas with high temperatures. Using a heat gun or micro blow-torch, you shrink the sleeving to form a tight protection around your cable and/or terminals to offer chemical and abrasion protection. Heatshrink sleeving is also available in adhesive-lined variants. These have a heat-activated glue on the inside of the sleeve that melts and re-solidifies to prevent moisture ingress, offering excellent protection in harsh environments such as external or marine applications.

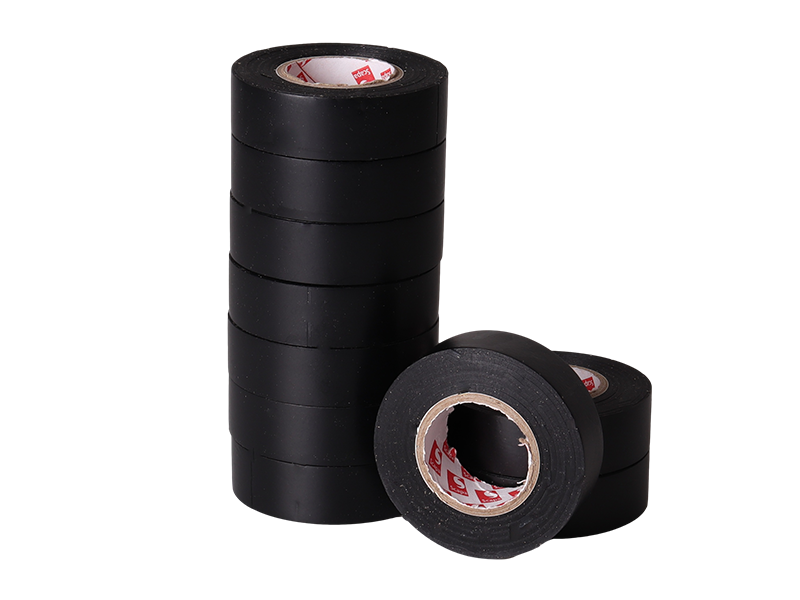

Tape

Tape is a very handy form of cable protection & management and is available in various types for different applications. It can help with identifying cables and protecting them against abrasion, water ingress & heat and it's always useful to have some in your toolbox. Tape comes in many different colours and styles, meaning there is nearly always something that will meet your needs. Non-adhesive PVC tape or cloth tape can be used to wrap looms, adhesive tape can be used to identify cables or seal the ends of sleeving, fleece-lined tape is used for wrapping cable and preventing rattling noises from vibration in vehicles, & foil/aluminium tape is used for heat resistance in areas such as the engine bay.

Disclaimer - The information contained in these articles is provided in good faith and we do our best to ensure that it is accurate and up to date, however, we cannot be held responsible for any damage or loss arising from the use or mis-use of this information or from any errors or omissions. The installer is ultimately responsible for the safety of the system so if you are in any doubt, please consult a qualified electrician. |

12 Volt PlanetAuto & Marine Electrical Components |

(150 x 150 px).png)

(150 x 150 px) (1).png)

(150 x 150 px).png)

.png)

(150 x 150 px) (1).png)

(150 x 150 px) (1).png)

(150 x 150 px) (2).png)

(150 x 150 px) (2).png)